Biological Filter: Trouble Shooting Guide

Background

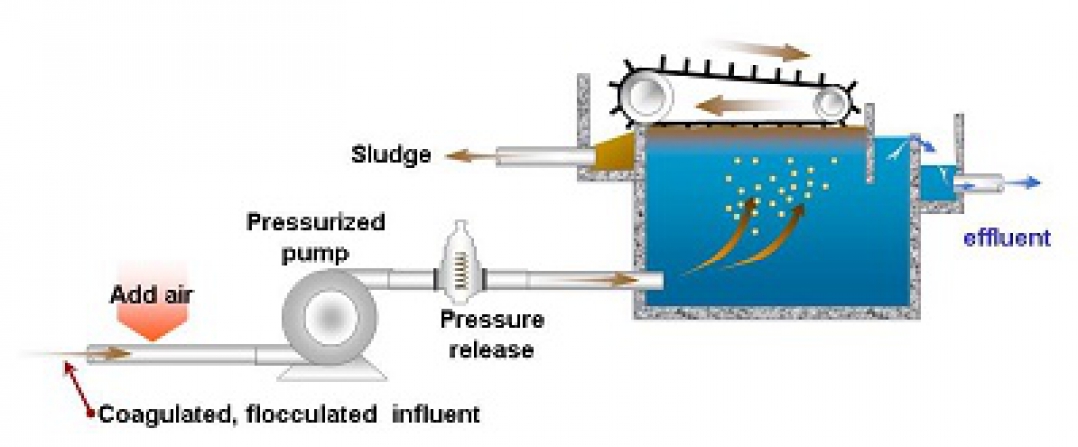

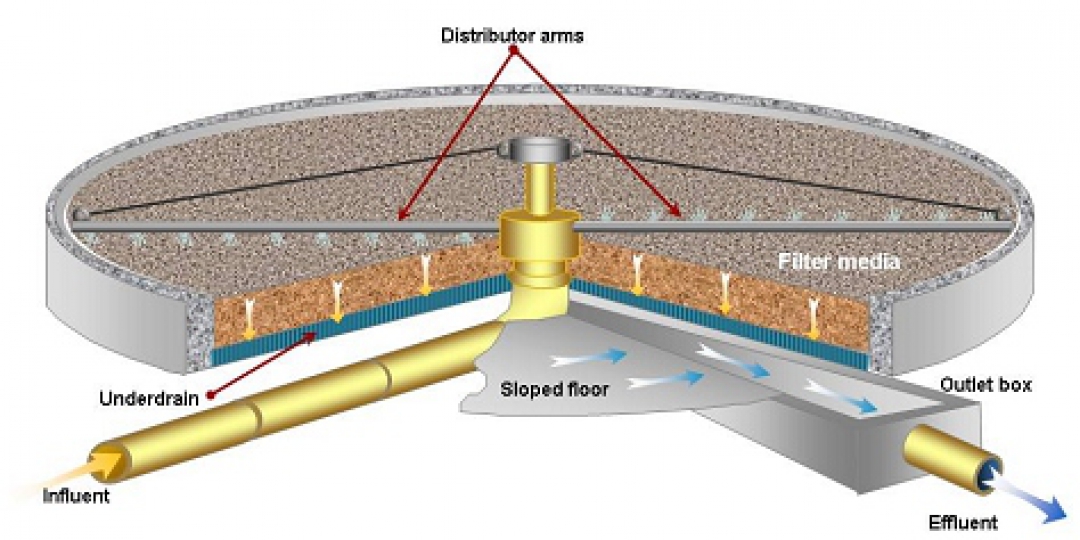

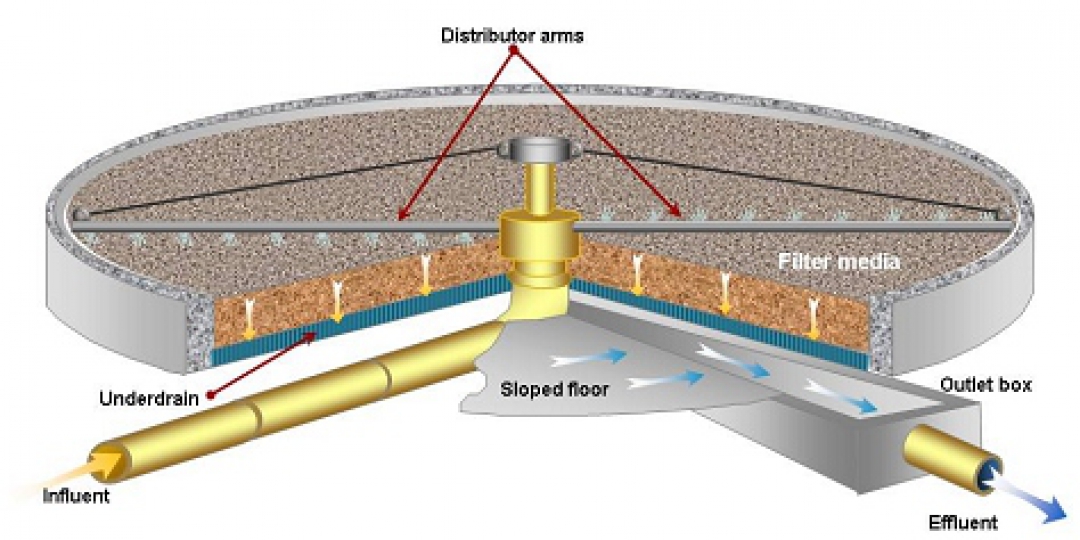

One of the earlier methods of treating sewage was to run it into a tank filled with loose stone. After some 12 hours contact, the sewage was drained away and the stone left in contact with air. After a period of time a biological slime grew on the stone, which affected the oxidation of the sewage. These units were known as contact filters. A modification to convert them to continuous operation, rather than batch, was made in 1893. The sewage was distributed across the surface of the contact bed by means of a moving mechanism. This was to prevent all the sewage falling on one spot and short-circuiting the greater mass of stone. A biological filter (shown in the sketch below), also known as tricking or percolating filter, was developed from this concept

Description

The filter consists of an outer shell normally made of concrete. Under-drains on the floor of the filter allow for the collection of the effluent from the bottom of the filter and allow for the free passage of air through the filter, which is important, as the micro-organisms, which grow in a filter, require oxygen from the air to live.

The shell is filled with filter media, the most common being crushed stone which has been carefully graded. The size of stone commonly varies from 25 - 100 mm in diameter. The depth of the media also varies from 900 - 4 000 mm (a typical average is approximately 1 800 mm). The filter media can also consist of coke, gravel, blast furnace slag, broken bricks or artificial media. The filter media should be weather resistant and not dissolve in the sewage.

The flow to the filter (from the primary sedimentation tanks) can be supplied by pumps or by gravity feed, controlled by a siphon. In the siphon system, during periods of low flow, no water passes directly to the filters but builds up in the dosing tank until a certain head has been reached. An air seal on the outlet siphon is then dislodged and the contents of the dosing tank are discharged to the filter. When the contents of the dosing tank have been discharged, the air seal on the siphon mechanism is automatically closed.

It is important in any distribution system that every portion of the media receives the same quantity of flow. In the case of circular filters, this means that distributor arms must be constructed to permit proportionately increasing amounts of effluent to be discharged from the inner pivot point to the outer circumference of the filter. Rotation is achieved by forcing water through the distribution holes and pushing the freely moving pipe away from the falling water. The available head of water and the size of the holes in the distribution pipe control the speed of rotation.

Principle of biological filtration

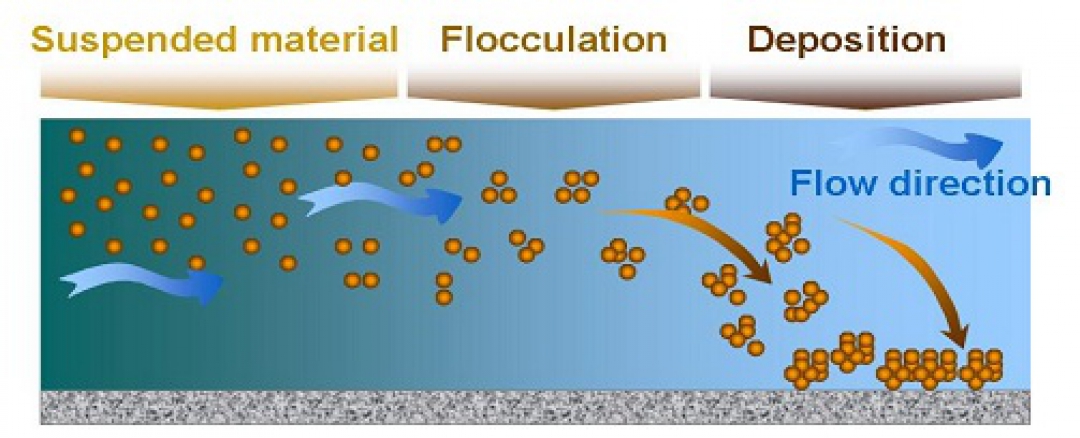

This is an aerobic process and distinct from sludge digestion, which is an anaerobic process. Sewage is a suitable source of food for the micro-organisms in a biological filter as it contains nitrogen, organic carbon compounds, phosphorus and trace elements. Air circulates in the voids between the media, taking oxygen to the slime layer on the surface of the media. As sewage trickles over the media, the various organic substances are absorbed onto the biological film thus supplying the organisms with food. Oxygen, which is present in the voids of the filter, dissolves in the water and is then transported to the slime layer. Metabolism of the substrate then takes place. If either food or oxygen is absent, this metabolism will stop. End products, which result from metabolism, are mainly water and carbon dioxide, which are liberated from the slime layer back into the main water flow. This process is most efficient when the slime layer is thin and totally aerobic.

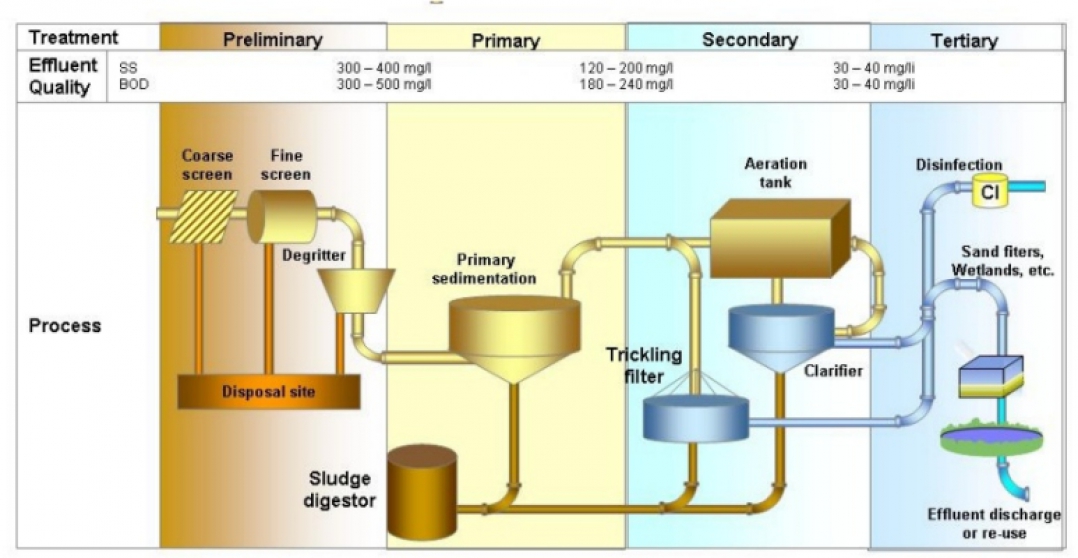

Activated sludge process

What is activated sludge?

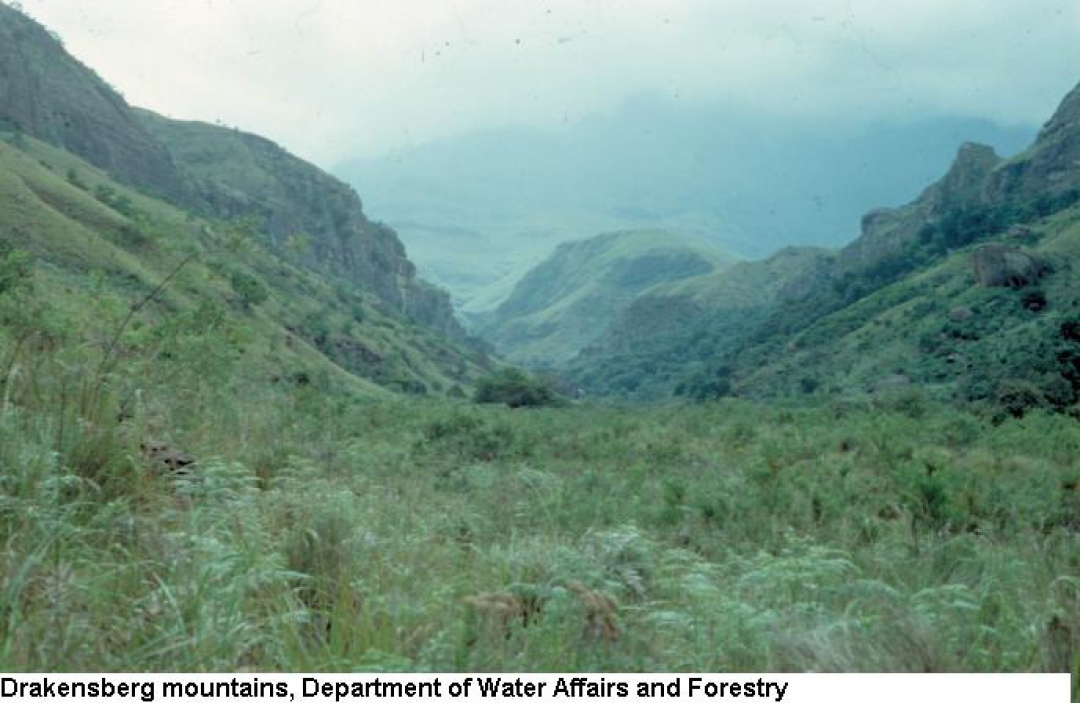

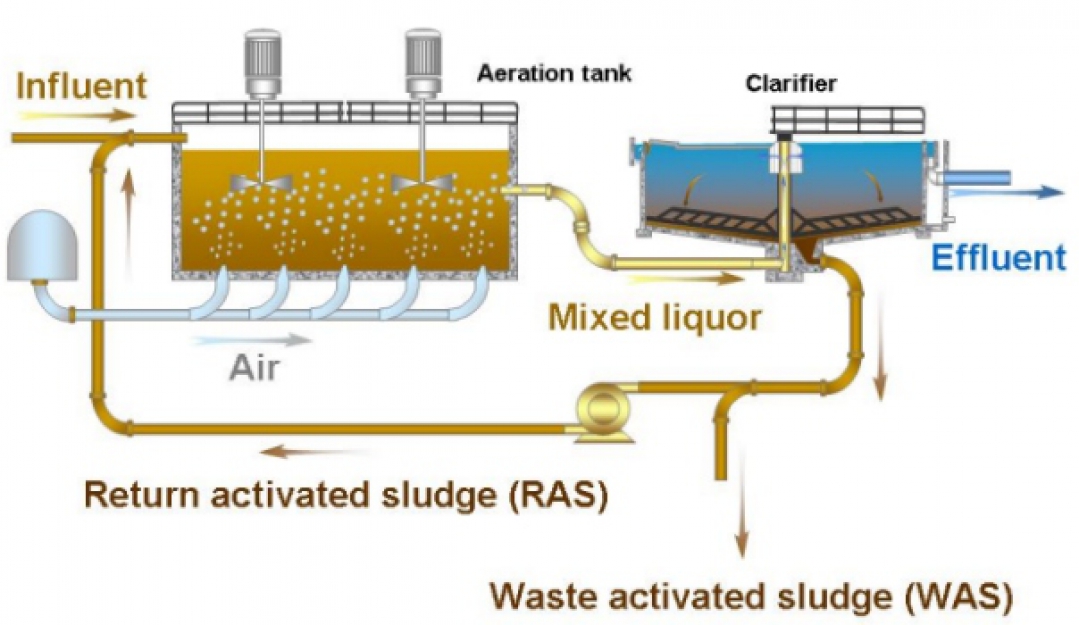

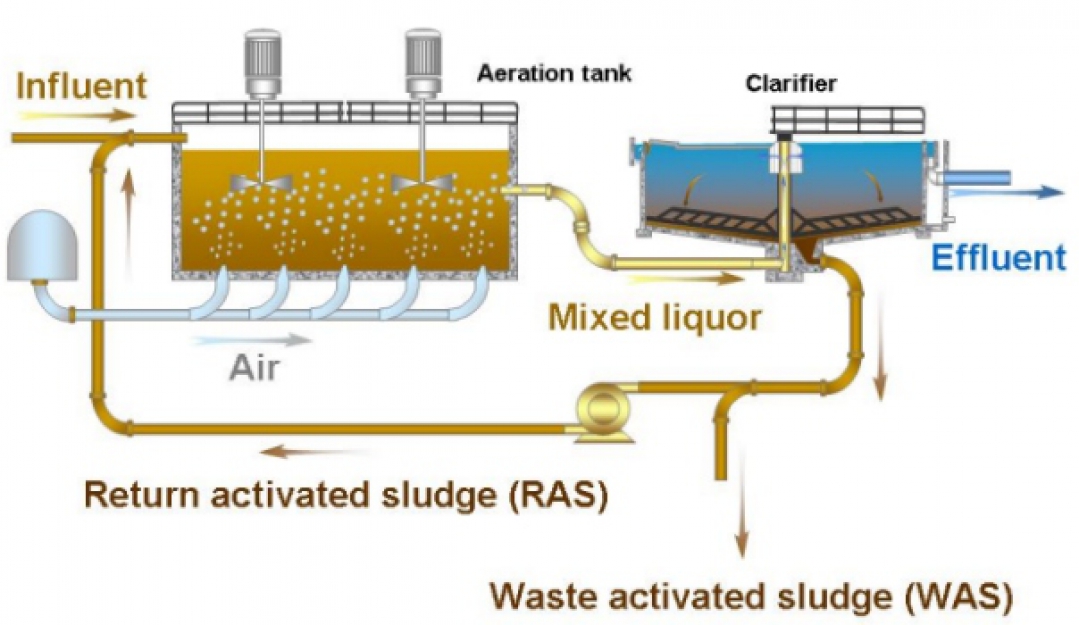

The process was discovered by the aeration of holding tanks for distributing raw sewage onto land. It was noticed that the nature of the sewage improved during aeration, which was applied mainly to prevent odours from forming. This improvement was even more marked when some of the sludge that was suspended and settled to the bottom during decanting, was re-suspended during aeration of the following batch of sewage. This led to the Fill and Draw method of treatment by which the sludge was allowed to settle to the bottom before decanting the effluent, filling the tank again with raw sewage, re-suspending the sludge by aeration and repeating the decanting process. It was noticed that under these conditions the sludge became more active and this process was referred to as activating the sludge. The basic layout of an activated sludge plant is illustrated in the sketch below. The aeration basin is followed by a clarifier, where the active sludge is separated from the liquid and returned (pumped) to the aeration basin, together with the raw influent. The aeration basin or reactor, the clarifier and return sludge pumping form integral parts of an activated sludge system.

The wastewater, containing numerous organic compounds, serves as a food source for micro-organisms in the mixture of activated sludge. Air is supplied for the respiration or breathing of these organisms and also for keeping the organisms in suspension and in contact with the food source. The organisms use the food to obtain energy, thereby growing to form new micro-organisms, carbon dioxide and water. The mass of organisms is constantly passed to the clarifier to be separated by settling and recycled by pumping back to the aeration basin (return activated sludge – RAS). The surplus sludge (waste activated sludge – WAS) formed by the additional growth of organisms must be removed from the system to keep the total mass of organisms constant.

Reference 1: Water Institute of Southern Africa (2002): Handbook for the operation of waste water treatment plants. ISBN 0-958-45346-2